Project details

- Industry: Automotive

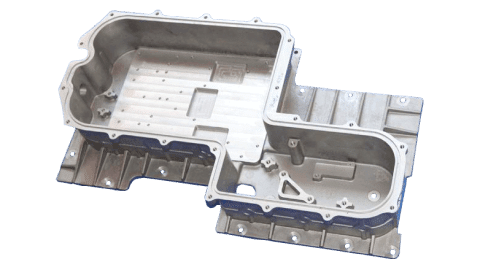

- Application: Gearbox housing

- Process: Aluminum die casting

- Challenge: The company tries to make sure the product is lightweight and has excellent precision and strength, and complex geometry.

To create large quantities of high-quality gearbox housing at a lower cost, an automotive manufacturer works with Echofast due to our splendid die casting services.

Case Analysis

As one of the core components in the automotive transmission system , the gearbox housing plays a significant part in the connection and fixation of the gearbox. It has higher requirements for quality and performance, including strength, stiffness, sealing and stability. Its processing accuracy directly determines the overall performance and life of the gearbox. As aluminum is a relatively lightweight material, the use of aluminum die casting in the automotive industry helps to reduce the weight of the car ,improve the performance and save fuel. In the production process, the gearbox housing is prone to defects such as shrinkage porosity and welding hot breaking, significantly affecting its performance. The issue should be dealt with carefully with advanced testing equipment.

Solution

Taking the metal properties into consideration, our professional team recommends aluminum die casting for this company to simplify the supply chain and dynamically scale the manufacturing capacity. Mold analysis and die-casting defects analysis are employed to forecast the related manufacturing risks, further improving the quality of the final product.

Aluminum die casting is most commonly used in the automotive industry because aluminum is lightweight and has excellent corrosion resistance, thermal conductivity, and mechanical properties.

To achieve the goal of being lightweight, Echofast utilizes common alloys such as ADC12, ADC10 and A380. We give priority to ADC 12 in terms of material, and the wall thickness of the housing can be reduced to 2-3mm, the surface roughness can reach Ra6.3μm, and the machining allowance can be as small as about 1mm. The housings can be tested for gas porosity with flaw detection machine to see if they meet the needs of the company. The third-level standard can be met and the product qualification rate reaches 98% in Echofast.

Product Used

Aluminum Die Casting

Outcome

The gearbox housing manufactured in Echofast exhibits high strength and rigidity, smooth surface, no or very few small gas porosity, and precise dimension tolerance.Working with Echofast, the company can get high-quality parts while greatly reducing production costs, shortening production cycles and improving economic benefits.

Client Feedback

The collaboration between Echofast and us contributes to speeding our gearbox housings to the market, ensuring unsurpassed quality and a high level of reproducibility. The result is more than satisfactory, and we are looking forward to our next cooperation.