Polyoxymethylene (POM), also known as acetal,polyacetal, and polyformaldehyde, is a high-performance engineering thermoplastic with high-tensile strength, stiffness and high-wear resistance. The material offers excellent creep resistance, hardness and rigidity, making it ideal for the production of parts that are in harsh environments and high wear applications.

Echofast is an experienced mold manufacturing partner with expert team and advanced equipment. We have confidence in producing excellent polyoxymethylene (POM) products while offering a easy and fast manufacturing experience.

Applications Of POM Injection Molding

Polyoxymethylene (POM) is well-suited for a wide range of applications due to its strength and durability. Common applications include:

Injection Molding Process At Echofast

- Load your 3D CAD file to get an injection mold quote

- After the order is confirmed, Echofast starts the export mold order process

- You will receive a 3D complete mold design for review and approval

- After the design is approved, Echofast starts manufacturing the injection mold.

- Sample approval and trial production

- Tooling delivery

What You Need to Know About Injection Molds

Injection molds are a larger investment, and you need to make sure that your custom injection mold meets specifications, as even a slight deviation can cause issues such as burrs during the molding process, which will result in your finished part being of lower quality. And it may take extra time to clean the parts. That’s why it’s important to choose a mold manufacturer that produces high-quality molds, and here are some important things you may want to know:

Mold material

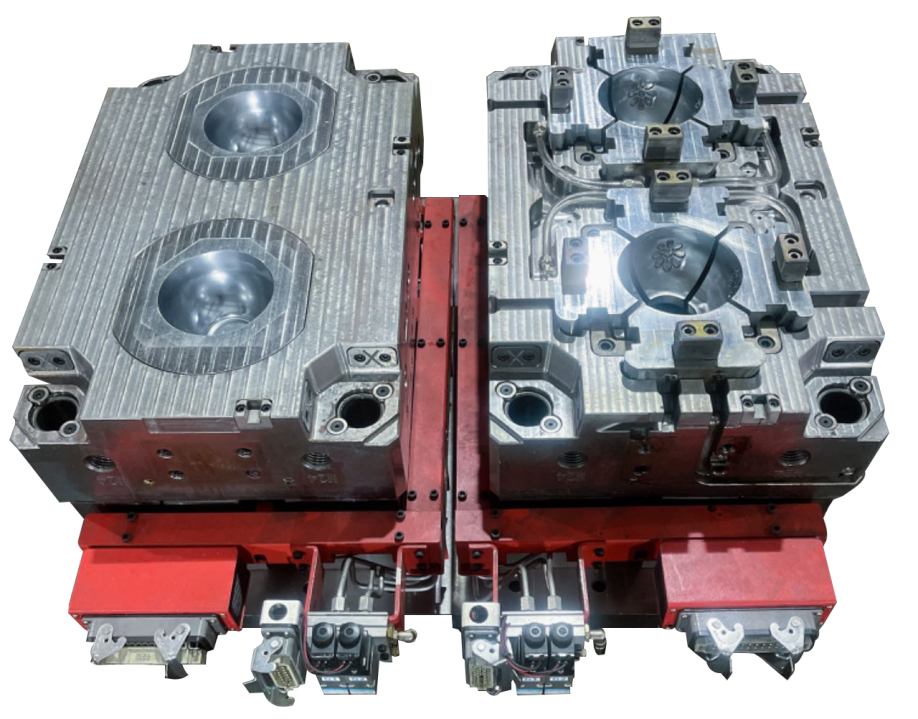

Echofast offers a full range of production injection molds for you to run in your own facility or at your designated manufacturing facility. Injection molds will be designed and manufactured according to American/Western standards. Depending on the products being produced, these molds will use specific steel types, including 718/718H, S136/S136H, NK80 or customer-required steel types. And our molds are optimized for production on your injection molding machine, with details like cooling line connections ready for your existing setup.

For injection molds suitable for differrent materials, we will consider factors such as the wear resistance of the mold, production cost and surface finish of the product. Usually we will choose the following types of steel:

| Mold Steel Material | Characteristics | Applications |

|---|---|---|

| P20 Steel | Pre-hardened mold steel with good toughness and hardness Easy to machine and polish Hardness between 30-40 HRC | Medium-volume production molds, such as automotive parts and appliance housings |

| H13 Steel | Hot work mold steel with excellent hot strength and toughness Good heat resistance and wear resistance Hardness up to 50 HRC | High-temperature, high-pressure injection molding environments requiring long lifespan and high wear resistance |

| S136 Steel | Stainless mold steel with excellent corrosion resistance and polishing performance Hardness between 50-52 HRC High purity and good toughness | Molds for products with high surface quality requirements, such as medical devices and cosmetic packaging |

| 420 Stainless Steel | High-temperature, high-pressure injection molding environments requiring long lifespans and high wear resistance | Molds requiring high corrosion resistance, especially in environments needing frequent cleaning and sterilization, such as food and medical fields |

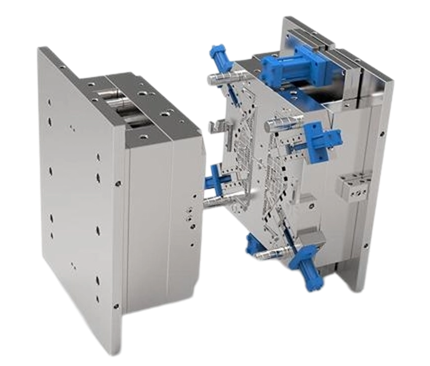

Injection mold design

For more complex injection molds, they must not only be manufactured according to specifications but also designed reasonably. Echofast can build mold injection system to your specifications including hot runner system, process, surface finish or texturing of the injection mold plastic. We can also match production specifications and mold designs based on your functional requirements for molds and injection molding.

| Design Consideration | Description |

|---|---|

| Filling System Design | Ensure even distribution of molten material into the mold cavities, minimize flow resistance and pressure drops. Use smooth and circular runners to reduce turbulence. Employ appropriate nozzle and temperature control systems. |

| Cooling System Design | Design effective cooling channels to facilitate rapid and uniform cooling of the injected material, reducing deformation and internal stresses. Include additional cooling channels in critical areas to accelerate cooling. Utilize rapid cooling techniques such as forced cooling or heated cooling mediums. |

| Mold Structure Design | Design mold cavities, cores, and dynamic mold components to ensure dimensional accuracy and surface quality of molded parts. Consider material shrinkage and flow characteristics when determining cavity and core dimensions and structures. Use high-strength and wear-resistant materials for mold components to increase mold longevity and production efficiency. |

| Venting System Design | Design proper venting systems to evacuate air and gases from the mold cavities, preventing air traps or voids in the molded parts. Incorporate vent grooves and channels in the mold structure to ensure adequate filling and venting. |

| Surface Treatment | Employ polishing or sandblasting techniques on mold surfaces to improve smoothness and quality, reducing surface defects caused by material during molding. |

| Part Design | Optimize part design to minimize wall thickness variations, sharp corners, or features that may cause stress concentrations or deformation. Use rounded edges and thin-wall designs to reduce stress concentration and improve part strength and toughness. |

| Mold Opening Mechanism | Choose appropriate mold opening mechanisms based on part geometry and size to ensure smooth demolding of finished parts. Consider multi-stage ejection or side-action mold structures for complex parts to maintain integrity and quality. |

| Mold Accessories | Design mold accessories and auxiliary devices such as ejector pins, locating pins, and sprue bushings for efficient mold operation and production stability. Utilize these accessories to improve mold usability and reduce manual intervention. |

| Production Cycle & Cost Control | Consider production cycle time and cost factors during mold design. Simplify and standardize design solutions to reduce manufacturing costs and delivery lead times. |

Cost & Mold Durability

The durability of injection molds is dependent on several variables, including part complexity, chosen material, and production volume. The largest factor affecting mold durability is the material used to construct the mold. Simple molds made from softer materials may only last for 100,000 cycles, while more complex molds made from high-quality steel can last for up to 1,000,000 cycles or more. The next variable is the type of plastic being used.

Abrasive materials or those requiring higher molding temperatures can reduce mold lifespan. Each production run adds wear and tear to the mold, potentially shortening its usable life. The overall durability of a mold also depends on proper maintenance and care. Regular maintenance, including cleaning and lubrication, can extend the life of a mold significantly.

While the initial investment in a high-durability mold can be substantial, the long-term savings and reliability can be significant, ensuring consistent quality and reducing downtime for repairs or replacements. Investing in durable molds is often more cost-effective in the long run, especially for high-volume production runs, where the cost per part can decrease substantially with a longer-lasting mold.

Need affordable mold services?

Price is a challenge for molds. Echofast offers highly competitive prices (10% below market price), making our services affordable for small manufacturers. You can talk to our mold experts, discuss your product idea, discover its manufacturability, and get the sample.

Alternatives To POM Injection Molding

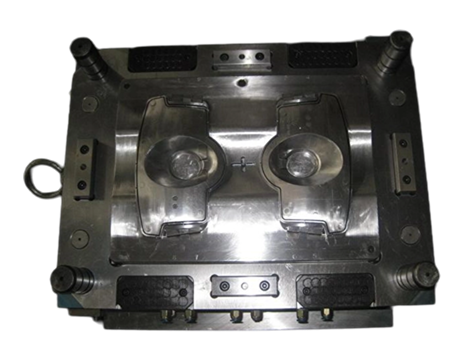

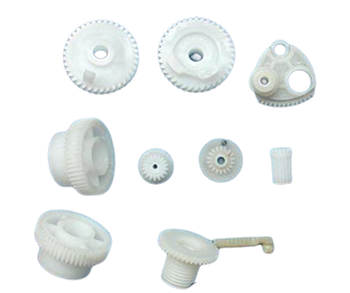

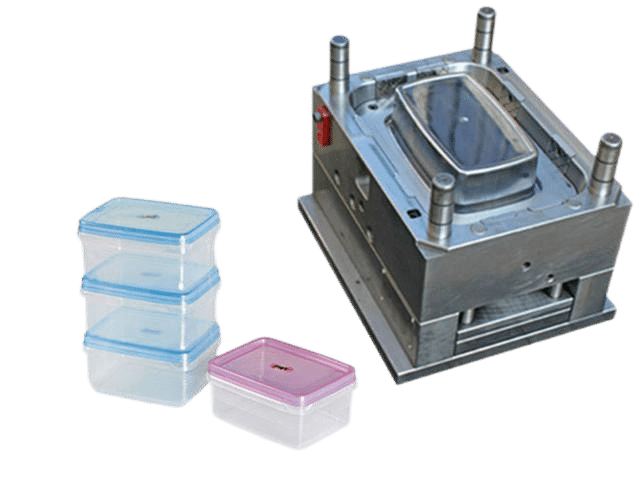

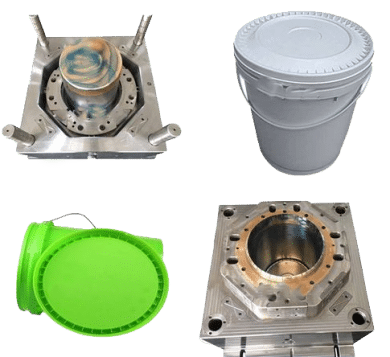

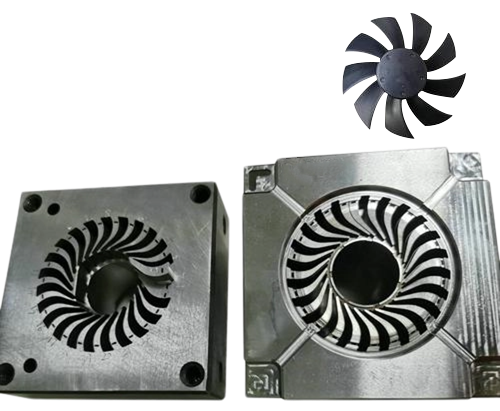

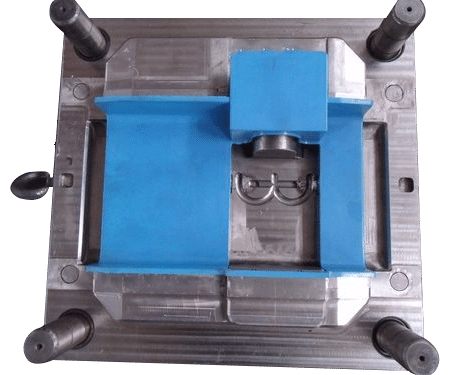

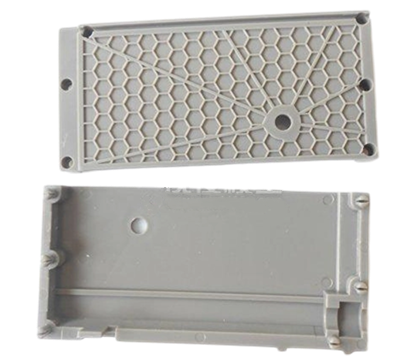

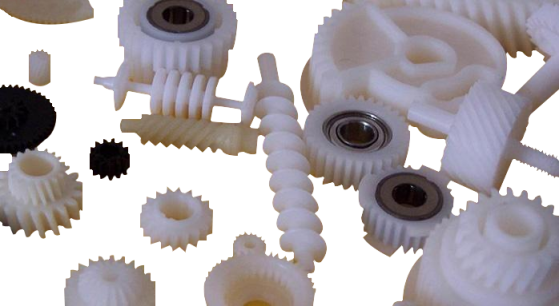

Gallery of Plastic Injection Molded Parts(POM)

The following is Echofast’s extensive gallery where you can see a number of outstanding and durable injection molded parts (POM). We offer the complete manufacturing solution for your project by delivering professional technical support.