Molds and Parts Manufacturing(Communication Equipment)

Echofast has rich experience in molds and parts manufacturing of communication equipment, offering comprehensive and customized solutions to bring your products to life.

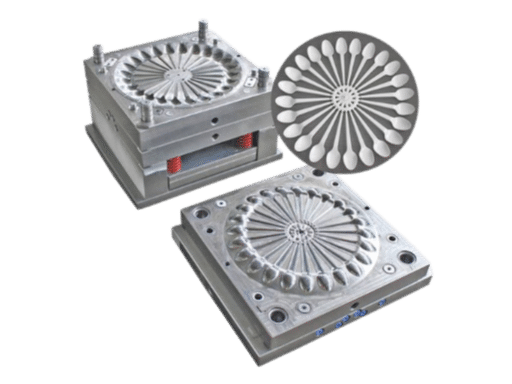

Mold Development And Customization

The mold development and customization of communication equipment is a professional and complex process. As a leading mold manufacturer, Echofast provides consumers with the relevant molds according to their specific needs.

The molds of communication equipment in our company have high precision and high production efficiency. We offer support throughout the whole process due to the team of experts with unparalleled skills and experience.

We have extensive experience in Communication Equipment parts manufacturing and mold development. We look forward to your better experience, and with Echofast you will find the process that best meets your needs and fits your product definition.

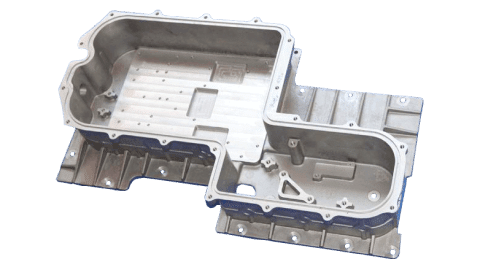

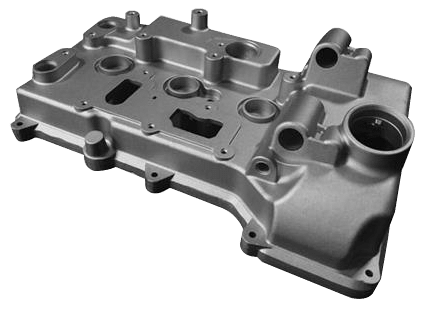

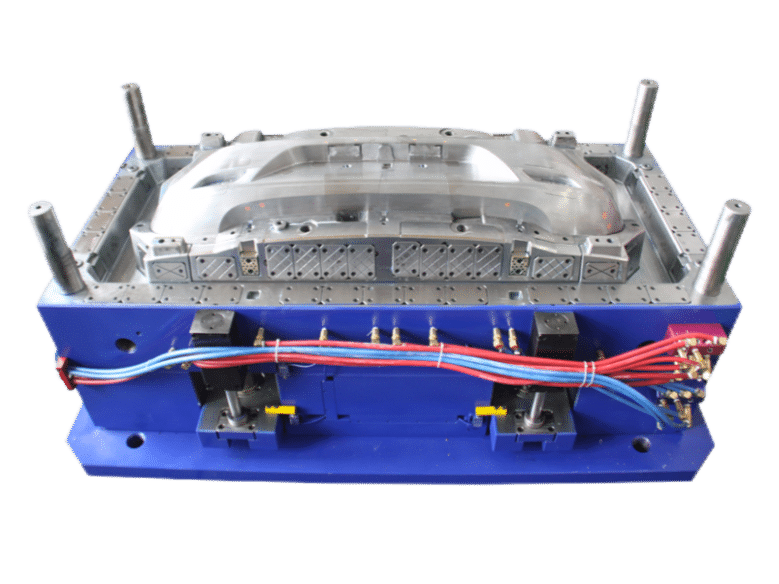

Communication Equipment Die Casting Mold

Communication equipment die casting molds refer to die casting tools specially used to produce communication equipment housings or parts. These molds are designed to withstand high pressure and high temperature, which can facilitate the production of metal parts with complex shapes and fine details.

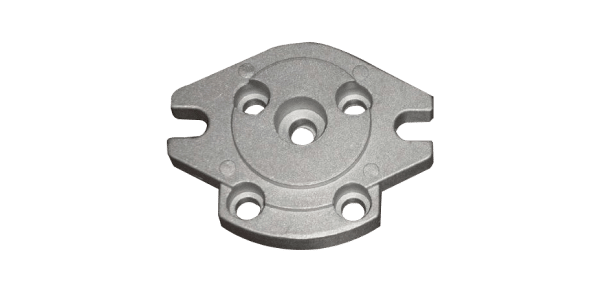

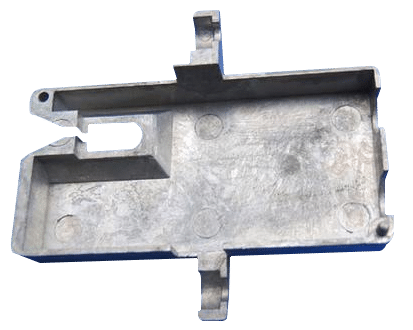

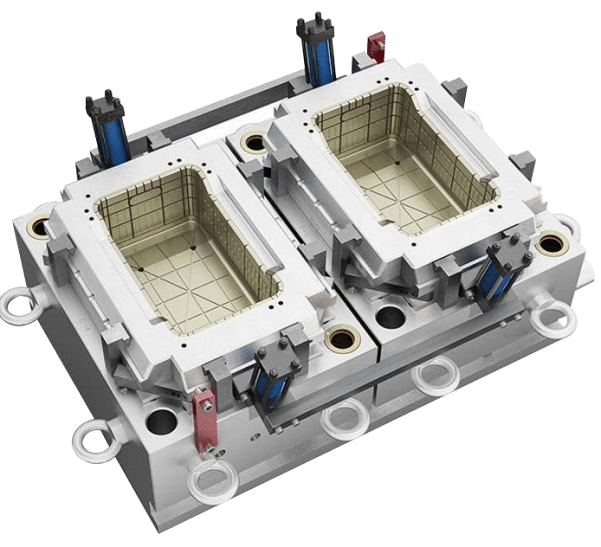

Common Die Casting Molds In The Communication Equipment Industry

With extensive technical knowledge and cutting-edge technology, Echofast can manufacture cost-effective die casting molds to streamline the mass production of communication equipment. Some common molds of communication equipment include:

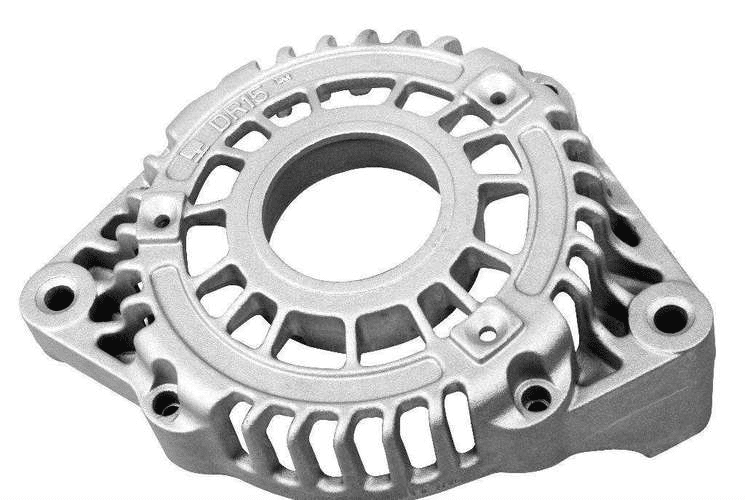

Common Materials used in Die Casting

Listed below are some common materials used in die casting. Echofast does well in producing motor parts made of aluminum.