Copper die casting is a manufacturing process that involves injecting molten copper into a mold to create complex copper parts. It is popularly used to produce parts characterized by high hardness and high corrosion resistance in high volumes.

At Echofast, our team of experts is committed to delivering high-quality copper die casting services. We specialize in producing complex-shaped parts with high precision and efficiency through the utilization of cutting-edge die-casting equipment and advanced engineering capabilities.

Applications Of Copper Die Casting

Copper die casting is often an excellent process for quickly manufacturing many parts in different industries. Some common applications include:

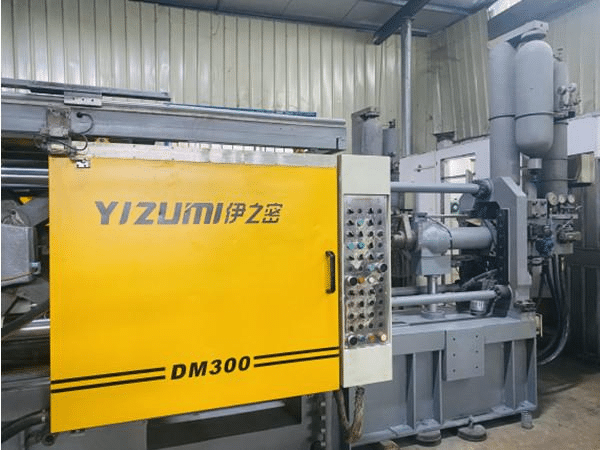

used on the die casting machines

LK die casting machines

YIZUMI die casting machines

Xinjiasheng die casting machines

Echofast Custom Service – Copper Die Casting

Copper die casting is a splendid process to manufacture die casts with high hardness, high corrosion resistance, good wear resistance, good and dimensional stability. With a focus on quality, Echofast offers comprehensive guidance and support throughout the entire process to meet the needs of our customers.

Echofast R&D Capabilities

Consultation and Design

We have the expertise and capability to provide a thorough and personalized consultation and guidance for consumers at the beginning, helping translate the ideas into precise designs optimized for copper die casting.

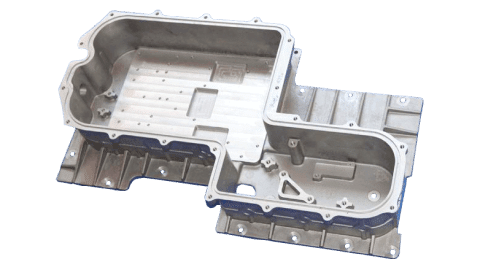

Tooling and Mold Design

We design a suitable mold structure and runner system according to the shape and size of the part.We leverage advanced CAD/UG/AnyCasting software and our in-house tooling capabilities for tooling and mold design to create high-quality molds with uncompromising precision.

Material Selection

At Echofast, we offer a diverse selection of copper alloys to meet the unique needs of consumers. Our committed and dedicated staff and professional engineers provide you with guidance in selecting the optimal alloy for your project, taking into account factors such as strength, corrosion resistance, and cost-effectiveness.

Die Casting process

We streamline the die casting process through our cost-effective production solutions and expertise. We utilize advanced die casting machines and implement rigorous quality control procedures to manufacture a number of copper die castings with high efficiency and productivity.

Finishing Operations

Skilled technicians in Echofast perform the related finishing operations to improve the surface finish and corrosion resistance of the castings.

Quality Assurance

Throughout the process, we uphold stringent quality control measures,including dimensional inspections, material testing and visual inspections. This can verify conformance to specifications, further producing parts with excellent dimensional accuracy, surface finish, and strength.

Packaging and Delivery

Once the finished copper die castings are carefully inspected, we offer packaging and delivery services according to your preferred specifications. As a trusted partner,we ensure timely delivery with flexible shipping options.

Need affordable mold services?

Price is a challenge in die casting, especially for molds. Echofast offers highly competitive prices (10% below market price), making our services affordable for small manufacturers. You can talk to our mold experts, discuss your product idea, discover its manufacturability, and get the sample.

Types Of Copper Die Casting

Cold chamber die casting

Cold chamber die casting, also known as cold casting, is a type of die casting where the machine’s feed system is unheated. It is particularly suitable for metals with high melting points like copper alloys. This is due to the unique characteristics of copper alloys. Compared to other die-casting metals such as zinc or tin, copper allows for better control over the casting process since it requires higher melting temperatures for optimal flow and solidification.

This process is a great option to maintain quality, efficiency, and the integrity of the final products. Cold chamber die casting excels in dealing with copper alloys, which tend to solidify rapidly. It mitigates challenges associated with premature solidification or excessive die wear, ensuring high-quality finished products.

Materials Of Copper Die Casting

Pure copper is not commonly used in die casting as it is prone to cracking, shrinkage, and porosity. Common metals used for copper die casting are copper-based alloys. They include brass, bronze, and beryllium copper.

Brass is an alloy of copper and zinc mixed in a certain proportion. It has excellent workability, machinability, and malleability. This metal is aesthetically pleasing and has corrosion resistance and electrical conductivity. Brass die castings have excellent mechanical properties and corrosion resistance, making it used in more decoration applications than functional applications.

Bronze is a copper alloy consisting primarily of copper and tin. It has excellent strength, durability, and wear resistance. Bronze die castings are suitable for use in harsh environments because of these properties, contributing to the production of durable, reliable, and high-performance components in various applications.

Beryllium copper is a copper alloy that consists of a mix of copper and beryllium. This alloy is ductile, weldable and machinable. Beryllium copper die castings have high strength and good conductivity of both heat and electricity.

Advantages Of Copper Die Casting

Copper die casting offers some huge advantages compared to other manufacturing processes, including:

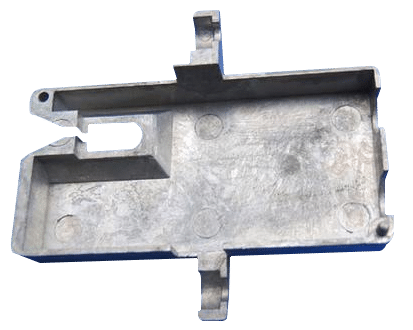

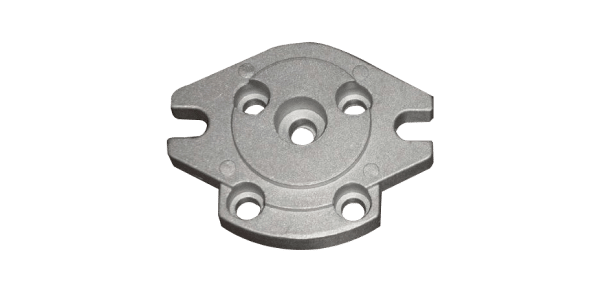

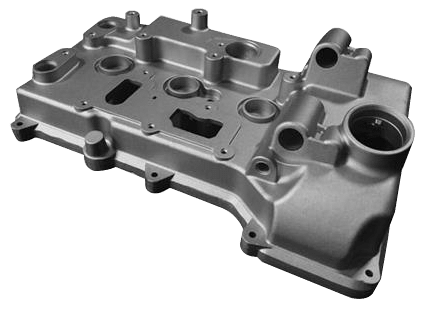

Complex Shapes: Copper die casting allows for the production of complex shapes and intricate details with high precision in one cycle because copper alloys are easy to machine.

High Product Quality and Attractive Appearances: Copper has high thermal conductivity, electrical conductivity, and excellent corrosion resistance. These two characteristics make it ideal for the high volume production of copper die castings. Copper die casting produces parts with tight tolerances and excellent surface finishes, resulting in high product quality and attractive appearances. It is commonly used in decorative applications where aesthetics are significant.

Recyclability: Copper die casting is a relatively environmental and sustainable process because of the exceptional recyclability and mechanical properties of copper, saving material costs.

Available Copper Die Casting Finishes

Copper die casting typically creates parts with smooth surface finishes, resulting in total machining elimination and reduction. In this stage, Echofast will take the measure of bright copper cleaning to obtain desired surface finishes with improved aesthetics. It refers to thoroughly clean the stains, impurities, spots, oil stains and other dirt on the copper surface to restore the bright color of the copper itself. It is also a necessary process before copper passivation to achieve high product quality.