Aluminum die casting is a manufacturing process where the molten aluminum alloy is forced into a mold under high pressure to create parts. Once the molten metal takes on the shape of the intended product and solidifies, the mold is is opened, and then the part is ejected. The process allows for the mass production of complex metal parts with close tolerances, and robust mechanical properties.

Echofast is a leading aluminum die casting mold manufacturer in Taizhou, Zhejiang, China., which is the hometown of mold. We promise to make high-quality products on demand while providing a fast and easy manufacturing experience.

Applications of Aluminum Die Casting

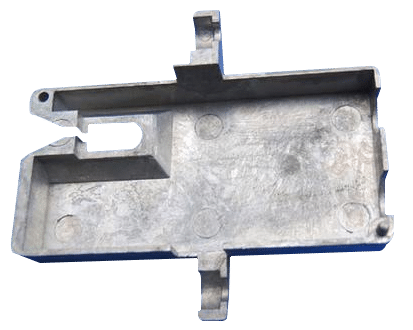

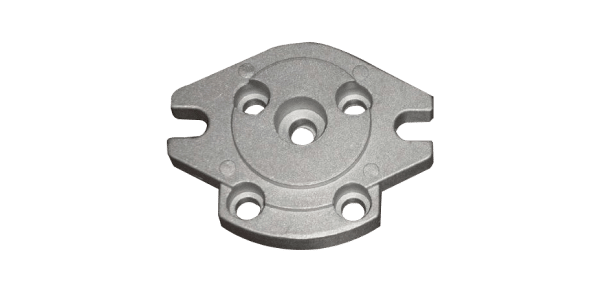

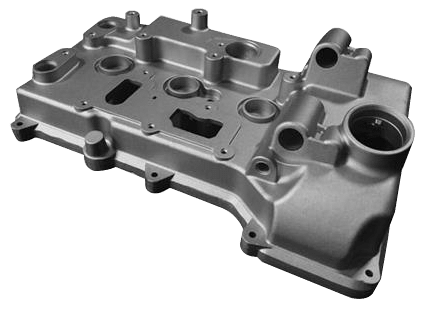

Aluminum die casting is not only lightweight, but also possesses high dimensional stability. It works well for complex part geometries. The process is generally used in a wide range of applications in Echofast, including:

used on the die casting machines

LK die casting machines

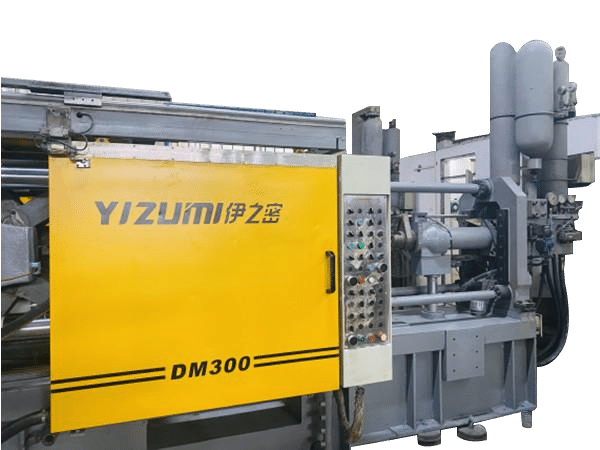

YIZUMI die casting machines

Xinjiasheng die casting machines

Echofast Custom Service-Aluminum Die Casting

Aluminum die casting is a perfect choice for creating high volumes of relatively lightweight but complex parts without sacrificing strength. With a combination of expertise, state-of-the-art facilities, and comprehensive services, Echofast can manufacture aluminum die casting molds and offer comprehensive services with great performance, durability, and efficiency. The aluminum die castings of one to five millimeters are available in Echofast with different aluminum alloys, which can reach the T6 state. They are produced with improved mechanical properties like good hardness and strength. At the same time, the air tightness of the die casting parts meets the requirements of consumers and ensures no blistering in the welding area, achieving optimal performance.

Echofast R&D Capabilities

Die Casting Mold Design and Manufacturing

Echofast specializes in the design and fabrication of high-quality molds customized to your exact specifications. With close cooperation with experts, we provide consultation and design assistance throughout the process by leveraging advanced CAD/UG/AnyCasting software and our expertise.

Prototype Development

Our prototyping process facilitates iterative design enhancement and validation, guiding you from initial concept to prototype realization swiftly and economically. It allows for thorough testing of design functionality and feasibility before proceeding to full-scale production,. This can mitigate risks and ensure the final mold meet your expectations. In this phase, the most suitable aluminum alloy for the prototype can be selected, with a lot of factors taken into consideration like strength, durability, and thermal conductivity.

High-Volume Production

With the advanced manufacturing capabilities and streamlined processes, Echofast can produce thousands or millions of parts with consistence and precision. We provide you with cost-effective production solutions, utilizing advanced die casting machines and implementing rigorous quality control procedures at every stage of production to ensure consistent and high-quality results.

Surface Finishing

Echofast offers a range of surface finishing options to greatly improve the performance and aesthetics of the aluminum die castings, and extend the service life. Our finishing services include powder coating, shot blasting, painting, plating, passivation and more.

Need affordable mold services?

Price is a challenge in die casting, especially for molds. Echofast offers highly competitive prices (10% below market price), making our services affordable for small manufacturers. You can talk to our mold experts, discuss your product idea, discover its manufacturability, and get the sample.

Types of Aluminum Die Casting

Cold chamber die casting, also referred to as cold casting, involves melting metal in a separate furnace and subsequently pouring the molten metal into an unheated chamber for injection into the mold under high pressure. It is the preferred die casting process for metals with higher melting temperatures, such as aluminum, magnesium, and copper alloys. It is ideal for producing high-quality aluminum parts with tight tolerances, excellent dimensional accuracy and surface finish. This results from the characteristics of aluminum alloys and the requirements of the die casting process.

Higher Melting Point: Aluminum alloys generally have higher melting points compared to materials like zinc or magnesium, making cold chamber die casting more prevalent in aluminum die casting operations.

Alloy Properties: Specific aluminum alloys are conducive to hot chamber die casting due to the presence of alloying elements capable of lowering the melting temperature. However, the majority of aluminum alloys utilized in die casting typically require higher melting temperatures, thus establishing cold chamber die casting as the preferred method. Cold chamber die casting affords superior command over the casting process, which ensure consistent quality and dimensional accuracy of aluminum parts.

A Diverse Range of Part Dimensions and Configurations:The cold chamber die casting process provides flexibility in producing larger and intricate aluminum parts, free from worries regarding premature solidification or constraints imposed by hot chamber die casting machinery. This technique accommodates a diverse range of part dimensions and configurations, rendering it applicable across multiple industries and applications.

Materials of Aluminum die casting

Common materials used in aluminum die casting include various aluminum alloys that are specifically formulated for die casting processes. To meet the unique needs of different die casting projects, Echofast selects aluminum alloys carefully based on the specific requirements of the application, including mechanical properties, surface finish, dimensional accuracy, and cost considerations. We offer the most commonly used aluminum die casting alloys, including:

| Alloy | Corrosion resistance | Resistance to hot cracking | Anodizing | Machinability | Common applications |

|---|---|---|---|---|---|

| ADC12 | Excellent | Good | Difficult | Good | Automotive applications, electrical components, and consumer goods. |

| A380 | Fair | Very good | Good | Good | Workbench vises and other hand tools, gear cases, lawnmower housings |

| A360 | Excellent | Excellent | Good | Good | Instrument cases, irrigation system parts, outboard motor parts, hinges |

| 383 | Good | Excellent | Good | Very good | Engine brackets, cylinder head covers, appliances, furniture, power tools |

| A413 | Excellent | Excellent | Good | Fair | Outboard motor pistons, dental equipment, street lamp housings |

| B390 | Fair | Good | Fair | Fair | Pistons, blocks, manifolds, and cylinder heads for internal combustion engines, brake cylinders |

| 518 | Excellent | Poor | Excellent | Excellent | Architectural castings, conveyor parts, marine and aircraft hardware fittings |

For example, ADC12 is the most commonly used material for aluminum die castings due to its good corrosion resistance, thermal conductivity and low cost.

A380 is the perfect jack-of-all-trades, offering a good combination of casting and product properties, and is the most commonly specified alloy for casting a wide variety of products.

A360 offers excellent corrosion resistance, pressure tightness, and very good fluidity when molten.

Advantages Of Aluminum Die Casting

Aluminum die casting has numerous benefits. These advantages are listed below: