What is Die Casting?

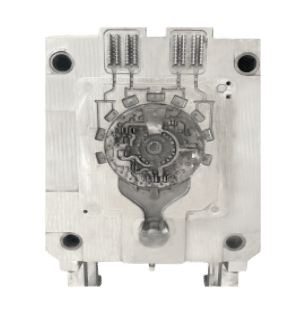

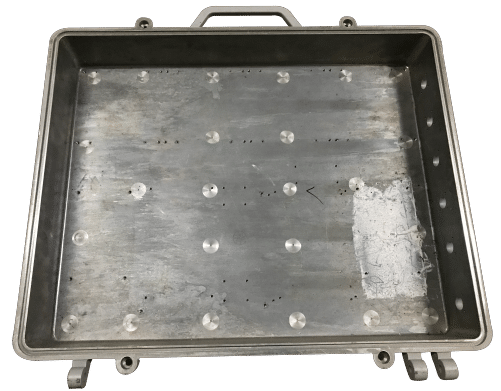

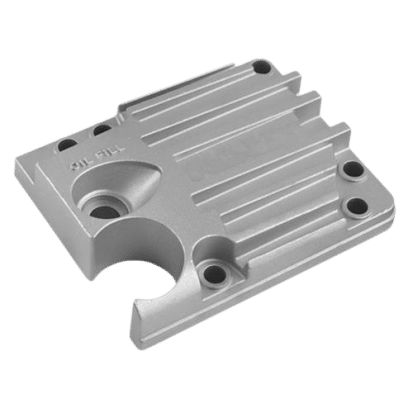

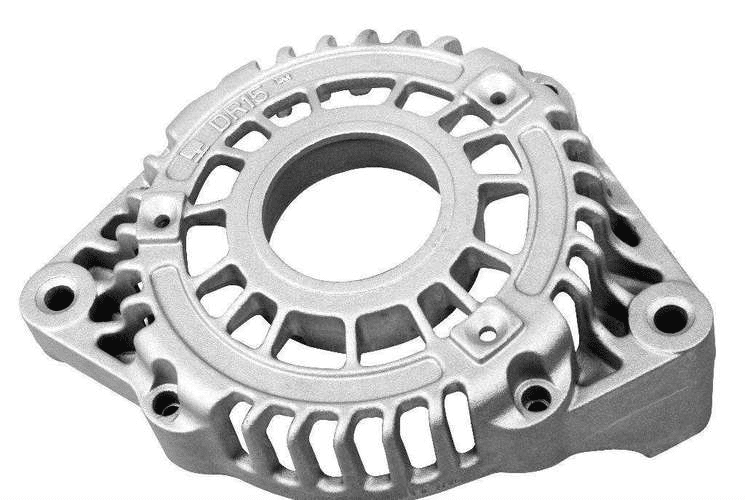

Die casting is a manufacturing process that forces molten metal into a mold cavity under high pressure to create large quantity of high-performing complex metal parts. The process requires a reusable steel mold for production, which is called a die casting mold. The mold consists of two sections clamped together, one stationary and one moveable.

As the molten metal in the mold cavity takes the shape of the part and hardens into place, the halves are separated to remove the casting. Common alloys used in die casting include zinc, copper, aluminium, magnesium, lead, pewter, and other non-ferrous alloys.

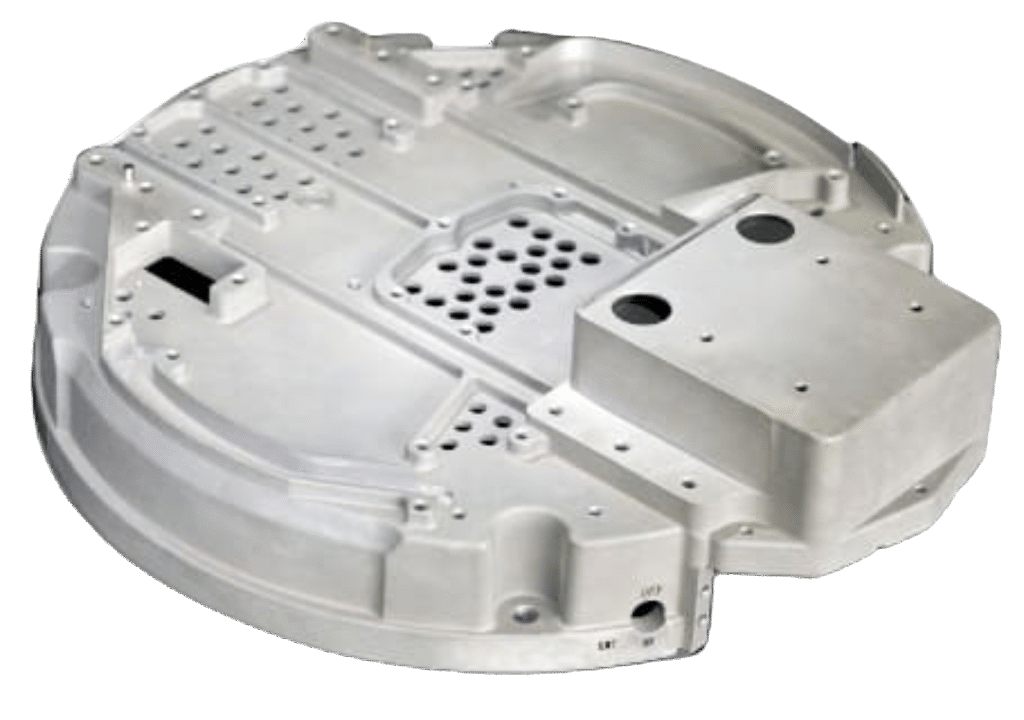

Die casting is a relatively simple process and well suited for the high-volume production of small-to medium-sized castings. Die casting parts can be made with tight tolerances and good surface finish, requiring few secondary operations.

Advantages of Die Casting

Disadvantages of Die Casting

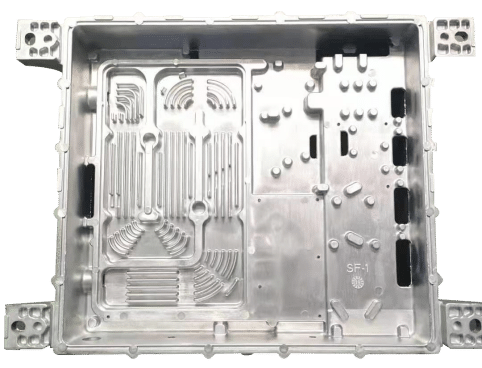

Die Casting Mold Design Process

Designing a mold involves processes that come with multiple categories.

- Preparation Phase: This is the phase where the validity of the product is evaluated from a dimensional and geometrical standpoint.

- Cavity Numbers: Cavity orientation, product count, and hypothetical time cycle have to be considered for the cavity mold’s best option.

- Projection Place: Projection has a significant role in the designing phase. It is also where the surface is created from the cavities plan.

- Die Volume & Shape: Volume and shape are essential in mold design. Here, the cavities’ sizes can be molded accurately.

- Simulation: This helps calculate the mold filling method. The modality depends on the filling process and process of the cast piece.

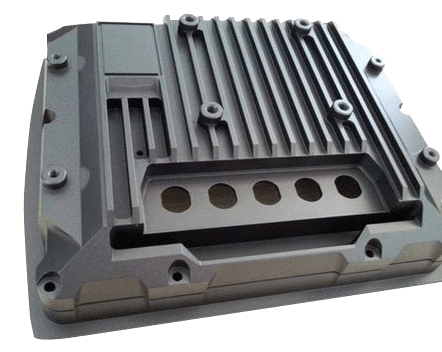

Die Casting Types Available from Echofast

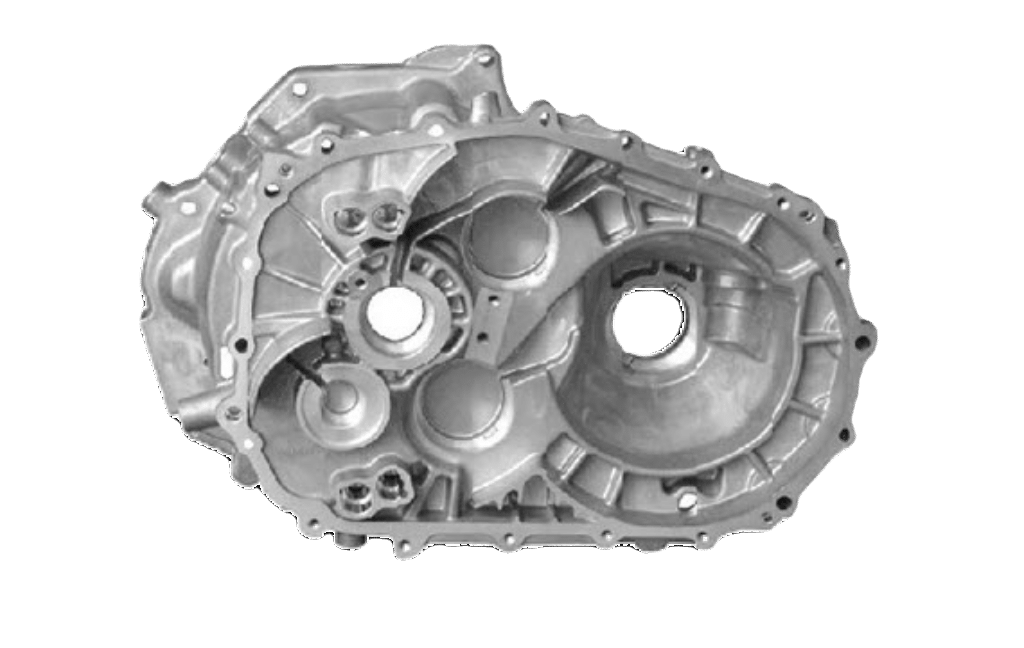

Cold chamber die casting, also referred to as cold casting, involves melting metal in a separate furnace and subsequently pouring the molten metal into an unheated chamber for injection into the mold under high pressure. It is the preferred die casting process for metals with higher melting temperatures, such as aluminum, magnesium, and copper alloys.

Hot chamber die casting, also known as gooseneck casting, is a fast-cycling casting process for metals with low melting points (i.e. Zinc, some Magnesium alloys). The molten metal is injected into the die mold under high pressure, where it rapidly solidifies into the desired shape before being ejected as a fully formed component.