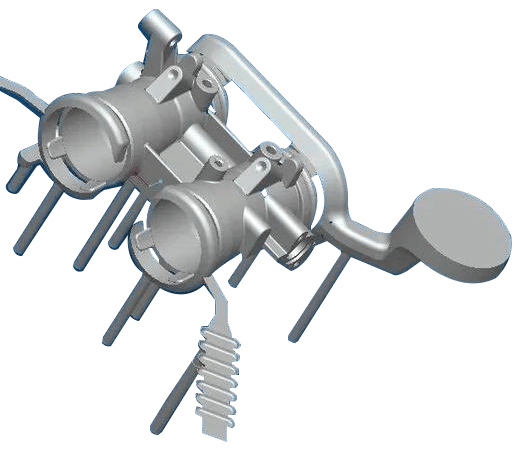

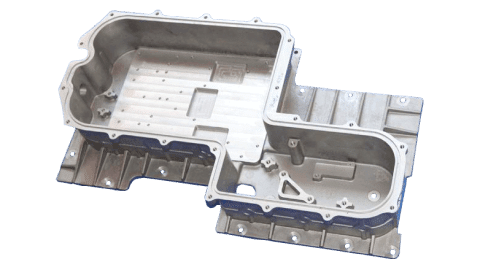

Die casting is a manufacturing process that produces high volumes of complex and tight-tolerance metal parts with a high strength-to-weight ratio. Thin wall die casting excels in creating stronger and lighter parts when compared with other casting methods.

As for non-ferrous alloy thin wall castings, the wall thickness can range from 2.0 to 4.0 mm. There is ultra-thin wall die casting with a wall thickness of less than 2.0 mm, which is often seen on aluminum alloy castings. Thin wall die casting is characterized by high production efficiency and excellent dimensional accuracy. It can create thin wall deep cavity castings for complex shapes with clear tours economically.

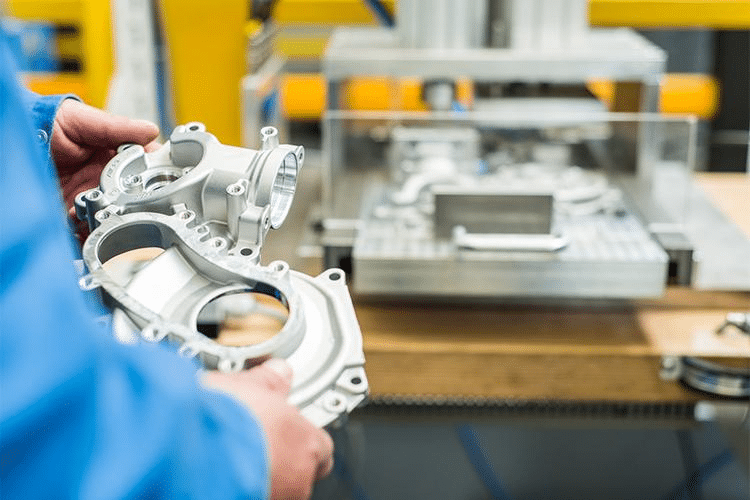

In Echofast, we mainly offer custom thin wall die-casting services with aluminum alloys. We can produce strong yet light parts for your thin wall casting needs.

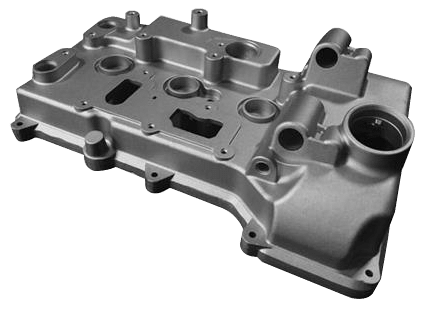

Applications of Thin Wall Die Casting

Thin wall die casting is used in a wide range of industries due to its ability to produce lightweight and durable parts.

Echofast Thin Wall Die Casting Materials

| Aluminum | ADC12 | Excellent corrosion resistance and mechanical properties; widely used in various applications such as automotive components and consumer goods. |

| A380 | Commonly used in automotive parts, electronic housings, and consumer goods. | |

| A360 | Offers good castability and machinability, suitable for intricate designs and thin-walled structures. | |

| 383 | Known for superior fluidity and pressure tightness, ideal for thin-wall casting applications. | |

| A413 | Utilized in automotive parts, electrical connectors, and industrial equipment. | |

| B390 | Exhibits excellent thermal conductivity and mechanical properties, suitable for heat transfer applications. | |

| 518 | High thermal conductivity and dimensional stability, suitable for heat sinks and electronics. | |

| Zinc | Zamak 3 | Known for excellent castability, dimensional accuracy, and surface finish. |

| Zamak 5 | Exhibits improved strength and hardness, suitable for a variety of applications. | |

| Magnesium | AZ91D | Good strength-to-weight ratio, excellent corrosion resistance, and machinability. |

| AZ91HP | Features enhanced creep resistance and thermal stability, ideal for high-pressure die casting. | |

| AM60B | Provides excellent ductility and impact resistance, suitable for automotive and sporting goods. |

Advantages of Thin Wall Die Casting

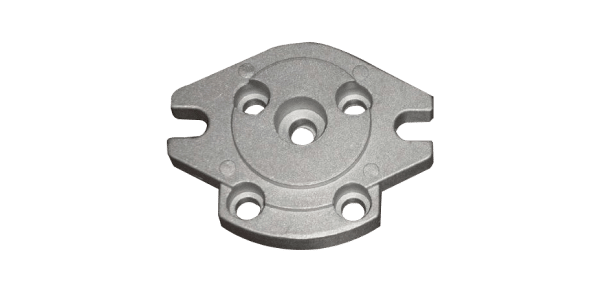

- Excellent strength-to-weight ratio

- Achievable net shape configuration

- Tight tolerances and high dimensional accuracy

- Efficient production

- Smooth surfaces (less machining)

- Nice surface finish

- Complex shapes

- Large sizes

- Reduced assembly

Disadvantages of Thin Wall Die Casting

- High initial cost due to prototyping and tooling requirements

- More porosity

- Tighter tolerances: Required for fillets/radii and drafts

Need affordable mold services?

Price is a challenge in die casting, especially for molds. Echofast offers highly competitive prices (10% below market price), making our services affordable for small manufacturers. You can talk to our mold experts, discuss your product idea, discover its manufacturability, and get the sample.