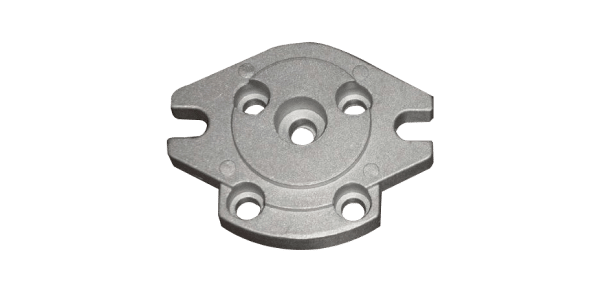

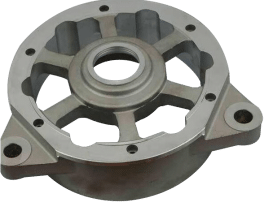

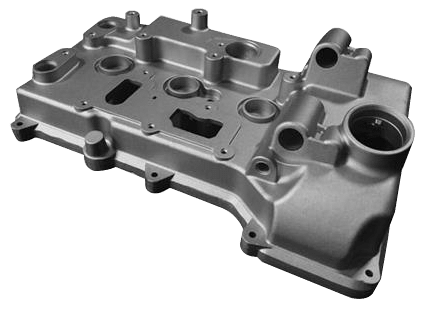

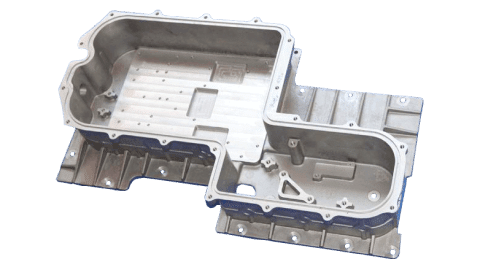

Zinc die casting is a precision manufacturing process wherein molten zinc is injected into a two-piece steel die, typically featuring one or more cavities, under high pressure. After the molten metal has cooled to the desired solidification point, the dies open, allowing for the ejection of the cast piece, which faithfully replicates the intricate details of the die cavity.

The process is often used to produce high-quality, intricate metal parts across diverse industries due to their excellent mechanical properties.

Drawing upon our extensive expertise in zinc die casting, Echofast specializes in delivering components with precisely engineered thin wall sections, maintaining exceptional dimensional accuracy. Our cutting-edge die-casting equipment and capabilities minimize the need for extensive machining during the production of zinc die castings. To help you find your ideal zinc die casting molds, we offer you the catalogue. You can download it whenever you need.

Applications Of Zinc Die Casting

Zinc is one of the most versatile and commonly used die casting metals for its superior durability. Zinc die casting finds application in several industries due to its versatility, strength, and cost-effectiveness. Some common applications in Echofast include:

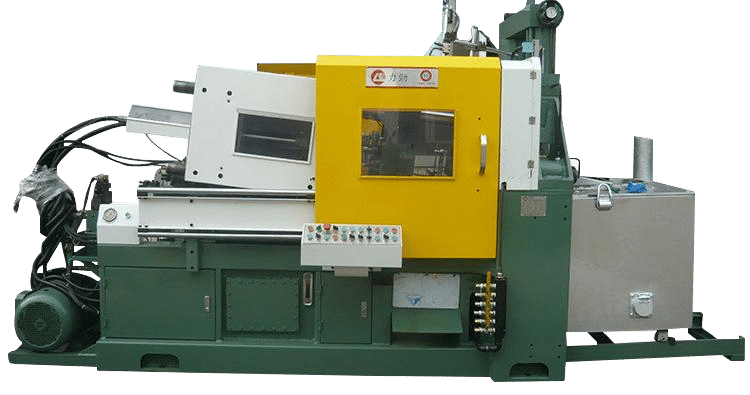

Used On The Die Casting Machines

LK die casting machines

Echofast Custom Service—Zinc Die Casting

Zinc die casting is great for precision manufacturing of products with excellent mechanical properties, good corrosion resistance, high precision and dimensional stability.

Echofast is the preferred choice for discerning manufacturers seeking top-quality zinc die casting solutions. We employ advanced vibration grinding technology to conduct surface polishing, chamfering, deburring, and gloss polishing of zinc alloy die castings. This process meticulously enhances the surface finish while preserving the original shape and dimensional accuracy of the castings. Additionally, we use this technology to effectively eliminate internal stress, which contributes to streamlining subsequent manufacturing processes. With the capability for automated operations and real-time monitoring of part processing, our system ensures efficient and error-free production. We prioritize product quality, expedited delivery, and cost control, thereby offering comprehensive solutions to meet consumers’ needs.

Echofast R&D Capabilities

Consultation and Design

We have the expertise and capability to provide a thorough and personalized consultation and guidance for consumers at the beginning, helping translate the ideas into precise designs optimized for zinc die casting.

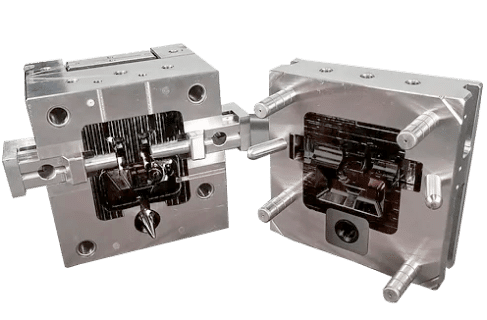

Tooling and Mold Design:

We design a suitable mold structure and runner system according to the shape and size of the part.We leverage advanced CAD/UG/AnyCasting software and our in-house tooling capabilities for tooling and mold design to create high-quality molds with uncompromising precision.

Material Selection

At Echofast, we offer a diverse selection of zinc alloys to meet the unique needs of consumers. Our team of experts provides you with guidance in selecting the optimal alloy for your project, taking into account factors such as strength, corrosion resistance, and cost-effectiveness.

Die Casting process

We streamline the die casting process through our cost-effective production solutions and expertise. We utilize advanced die casting machines and implement rigorous quality control procedures to manufacture a number of zinc die castings with high efficiency and productivity.

Finishing Operations

Skilled technicians in Echofast perform a series of finishing operations to improve the surface finish and corrosion resistance of the castings. These operations include trimming, deburring, machining, and surface treatments such as plating or powder coating as per your requirements.

Quality Assurance

Throughout the process, we uphold stringent quality control measures, including dimensional inspections, material testing and visual inspections. This can verify conformance to specifications, further producing parts with excellent dimensional accuracy, surface finish, and strength.

Packaging and Delivery

Once the finished zinc die castings are carefully inspected, we offer packaging and delivery services according to your preferred specifications. As a trusted partner, we ensure timely delivery with flexible shipping options.

Need affordable mold services?

Price is a challenge in die casting, especially for molds. Echofast offers highly competitive prices (10% below market price), making our services affordable for small manufacturers. You can talk to our mold experts, discuss your product idea, discover its manufacturability, and get the sample.

Types Of Zinc Die Casting

Hot chamber die casting, also known as gooseneck casting, is a fast-cycling casting process for metals with low melting points (i.e. Zinc, some Magnesium alloys). The molten metal is injected into the die mold under high pressure, where it rapidly solidifies into the desired shape before being ejected as a fully formed component. It is the most common die-casting method utilized for zinc alloys for the following reasons.

Lower Melting Point: Zinc alloys have lower melting points compared to other metals like aluminum or magnesium. They can melt at 385°C, so they are easy to die-cast.

Good fluidity: The excellent fluidity characteristic of zinc alloys results in faster cycle times and increased efficiency in the die casting process, making various complex parts easy to cast.

Easy to recycle: The proportion of old materials can reach about 40%. Therefore, when the hot chamber machine is operated, it can operate at low temperatures very stably. Old materials can be recycled in a closed furnace to avoid excessive oxidation residues. The risk of contamination of the molten metal can be reduced as well.

Materials Of Zinc Die Casting

Echofast casts two different zinc alloys: Zamak 3 and Zamak 5. Both of them offer superior flow and mechanical properties, and can be used to cast with intricate detail and close dimensional tolerances.

Zamak 3 is the most commonly used zinc alloy in die casting due to its superb dimensional stability and castability. It is a high conductivity copper-beryllium alloy used in applications requiring a combination of high thermal conductivity with moderate strength.

Zamak 5, based on high-purity zinc, is widely used in die casting for applications that are subject to high-stress levels. It has higher strength and less ductility than other members of the Zamak. This kind of metal is more readily plated, finished, and machined than Zamak 3.

Advantages Of Zinc Die Casting

Zinc die castings have many advantages. These are listed below:

Longer Tool Life

The low abrasion and erosion of tools associated with zinc alloys, coupled with their low operating temperatures, contribute to extended tool longevity. It results in significant cost savings.

Zinc die casting is a cost-effective solution for producing medium- to high-volume, complex metal parts. Zinc die casting surpasses other net-shape metal part processes in terms of efficiency because of its ability to deliver high production rates, minimize material waste, and shorten manufacturing cycles.

Zinc die casting is well-suited for the production of intricate and complex shapes due to the favorable properties of zinc alloys, including low viscosity and low erosion behavior in the molten state. High precision and low tool erosion can be made in the process owing to the excellent flow characteristics of zinc alloys. It allows for the filling of thin walls and tight tolerances with ease.

Excellent Balance of Mechanical and Physical Properties

Die cast zinc alloy creates tough and durable parts, which have higher yield strength and elongation than aluminum or magnesium. Zinc die castings deliver good thermal and electrical conductivity and corrosion resistance. As a result, they are suitable for applications exposed to harsh environments or corrosive elements.

Zinc die-cast parts are renowned for their smooth and uniform surface finish, necessitating minimal post-processing. This efficiency not only saves valuable time but also reduces costs throughout the production process.

Available Zinc Die Casting Finishes

Listed below are several zinc die casting finishes, but plating is the most commonly used for zinc alloys.