What is Injection Molding?

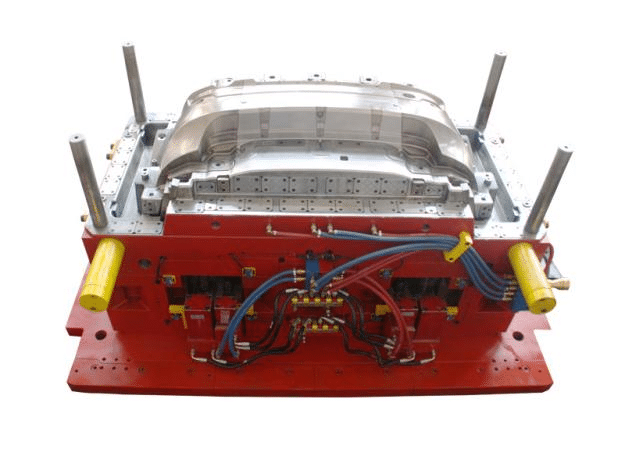

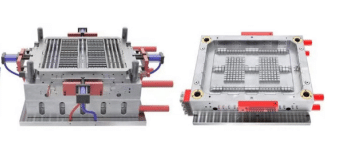

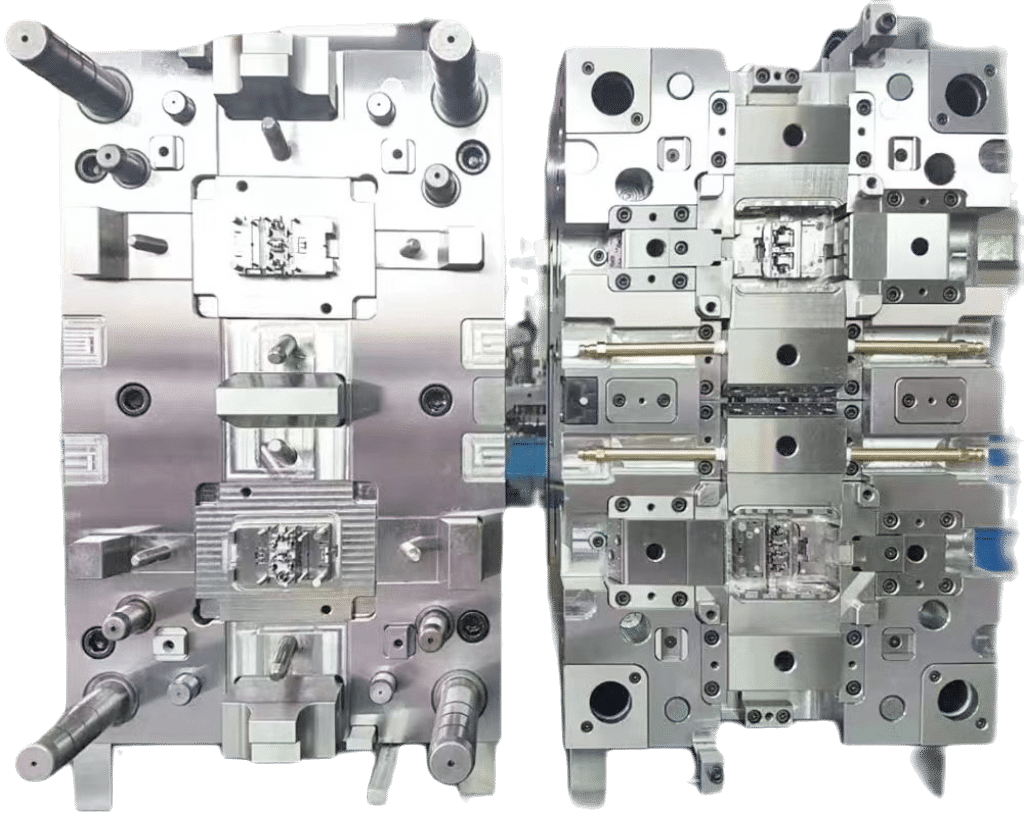

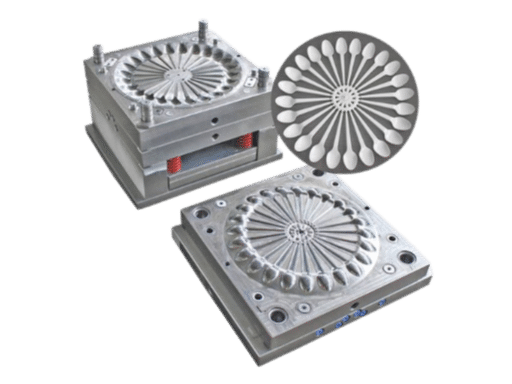

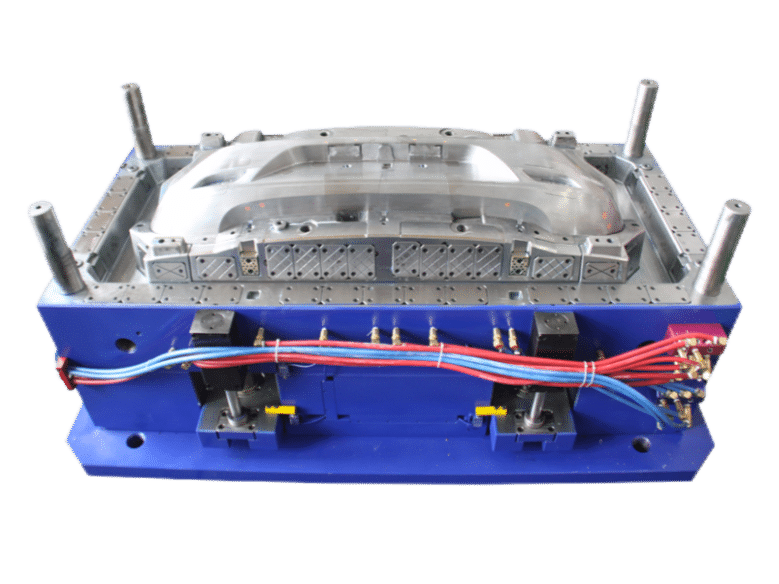

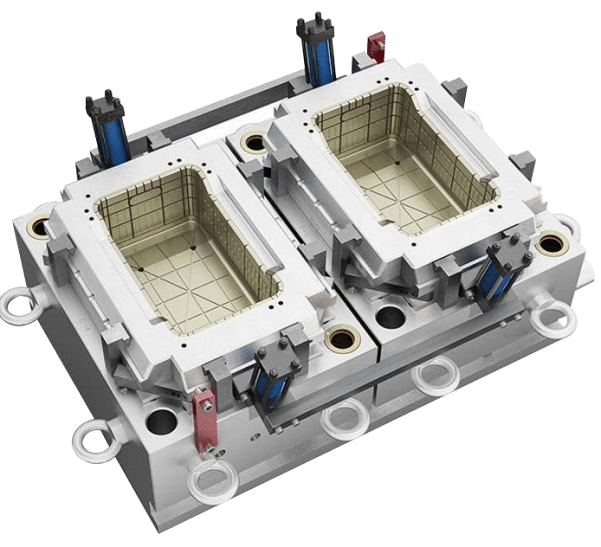

Injection molding is a manufacturing process that involves injecting molten plastic into a mold tool , which then cools, solidifies, and forms a plastic part. The process is ideal for producing parts with complex shapes and tight tolerances at scale due to its cost-effectiveness. Consistent quality across every part can be guaranteed due to the use of the same mold tool in the process.

Advantages of Injection Molding

Disadvantages of Injection Molding

Injection Molding Capabilities

| Service | Details |

|---|---|

| Lead Time | About 30 days, but the specific time is mainly based on the mold structure |

| Production Options | Domestic and international |

| Materials | Most plastics, including custom sourcing and matching; see materials list below |

| Machines Available | Single, multi-cavity, and family molds; 50 to 2,500+ injection molding tonnage; side actions including hand-loaded cores. |

| Inspection and Certification Options | ISO 9001: 2015 |

| Tool Ownership | Customer-owned with mold maintenance |

| Mold Cavity Tolerances | +/- 0.005″ when machining the mold and an additional +/- 0.002″ per inch when calculating for shrink rate |

| Critical Feature Tolerances | Tighter tolerances can be requested and may increase the cost of tooling because of additional sampling and grooming. |

| Available Mold Types | Steel and aluminum; Production grades range from Class 105, a prototype mold, to Class 101, an extremely high production mold. |

Classes of Injection Mold

| Mold Class | Cycles | Applications | Tolerance | Cost | Lead Time |

|---|---|---|---|---|---|

| Class 105 | Less than 500 cycles | Prototype testing | ± 0.02mm | Inexpensive to produce a very limited number of product prototypes | 7-10 days |

| Class 104 | Less than 100K cycles | Good for limited-production parts with non-abrasive materials | ± 0.02mm | Fall within low to moderate price ranges | 10-15 days |

| Class 103 | Less than 500K cycles | For low to medium-production parts | ± 0.02mm | Fall within common price ranges | 10-15 days |

| Class 102 | Less than 1M | Good for parts with abrasive materials and/or tight tolerances | ± 0.02mm | Fairly high price and made with materials of high quality | 10-15 days |

| Class 101 | Over 1M cycles | Extremely high production and fast cycle times | ± 0.02mm | Highest price and made with only the highest quality materials | 10-18 days |

Injection Moldings Design Guidelines

| Feature | Tip |

|---|---|

| Undercuts | Reduce undercuts, which will increase the complexity and cost of the tool ejection mechanisms, by adding in pass-thru coring. |

| Wall Thickness | Prevent wall sink and voids by maintaining an even wall thickness. Thinner walls reduce cycle time and reduce costs. |

| Drafts | Ensure parts are designed with a minimum draft angle of 0.5°, or up to 5°, for faces with medium textures. |

| Ribs/Gussets | Ribs should be 40-60% the thickness of outer walls and should still maintain draft. |

| Bosses | Bosses should be designed at a depth of 30% the wall thickness and with a 30% edge groove. Attach them to side walls or ribs for structural integrity. |

Injection Molding Materials

Custom injection molds manufactured in Echofast are typically made of steel, but dozens of plastic materials are available for injection molding. We can select the most suitable material meticulously to help you achieve outstanding and durable injection molded parts according to your strict specifications.

Surface Finishes

| FINISH | DESCRIPTION |

|---|---|

| PM-F0 | non-cosmetic, finish to Echofast’s discretion |

| PM-F1 | low-cosmetic, most toolmarks removed |

| PM-F2 | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| PM-T1 | SPI-C1 + light bead blast |

| PM-T2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | grade #2 diamond buff, 1-2 Ra |